Filter Press Plates

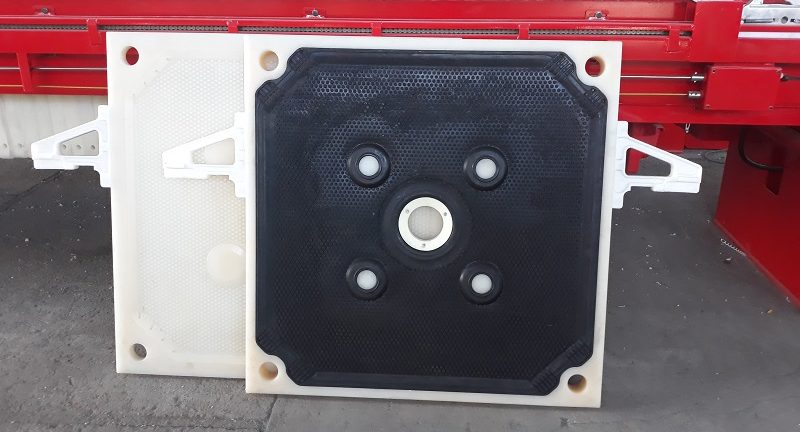

The plates, as a significant component in the operation of the filter press, are made from hard and durable materials, designed and constructed according to the characteristics of the feed and the desired final moisture content. They are generally divided into two categories: fixed-volume plates and variable-volume plates.

Fixed-Volume Plates (Chamber Filter Plate)

These plates are designed and constructed from high-quality, durable materials in various sizes. During the operation of the filter press, two plates form a closed chamber together, where the materials are placed. After applying pressure, the solid cake resulting from filtration is formed in this space.

Variable-Volume Plates (Membrane Filter Plate)

In the design of these plates, in addition to a robust and impermeable body, a flexible membrane is also utilized. This allows for water injection in the internal space between the membrane and the plates, which also reduces chamber volume and applies additional pressure to the cake. These plates are used when there is a need to reduce moisture in the final cake.